Ask any food industry expert; the latest trend in the world of food is personalised, tailored nutrition – a diet plan that suits your lifestyle and eating habits in an affordable and convenient way.

With a rise in dietary requirements ranging from veganism, vegetarianism, gluten free, dairy free, sugar free or a mixture of multiple, it is no wonder that food manufacturing and processing facilities need to be more careful than ever to avoid cross contamination cases that could lead to illness or in some cases litigation.

Tailoring a facility to both meet the demands of the consumer and perform to the best of its ability, whilst reducing the risk of contamination, can easily be achieved with bespoke flooring options. Let’s take a look.

Coloured Zones

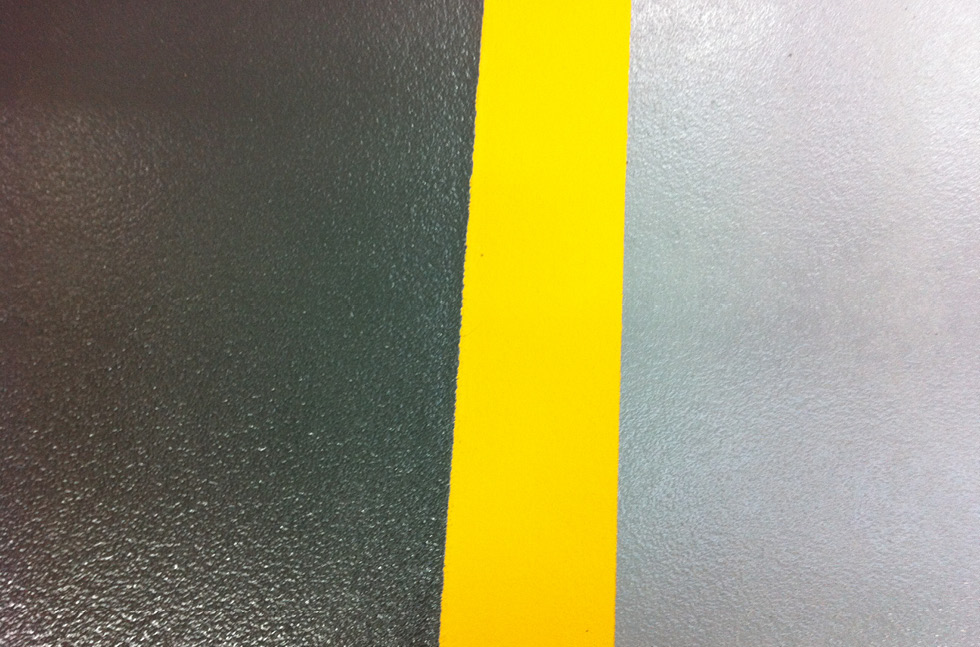

Colours can be used to various effects in food and beverage facilities, but to signify any real change, the colours must be prominent enough to be noticed and obeyed from afar.

One way that this can be achieved is to incorporate colours into the floor and use the different coloured flooring to zone a space. This can greatly reduce the risk of cross-contamination, as a facility manager could rule that workers handling raw meat must stay in the red zones, whilst those packaging cooked meat must stay within the blue zones, for example.

Coloured sections can zone spaces and identify areas where hazards can be present

Contamination can come in many forms however and the majority of the time there is no physical sign that contamination has occurred. This doesn’t always result in illness either, contamination can go against a consumer’s belief, rather than cause them physical harm.

The number of vegans in the UK alone quadrupled between 2014 and 2018, heavily increasing the demand for vegan foodstuff, meaning that many facilities began producing vegan produce alongside non-vegan produce. Cross contamination could be a major issue here, and facilities would need to be very careful to ensure that this did not happen.

Colour could be used once more to visibly show areas where vegan produce is handled and packaged, so that those working with non-vegan produce can easily see the boundaries that they should not cross.

Zones and demarcation can separate a space

Antibacterial Solutions

If foodstuff is dropped in or outside its designated zone, being able to clean it up quickly and easily must be a top priority. If it is not cleaned, you run the risk of it being walked across the zones on the shoes of employees, or the wheels of trolleys, leading to contamination.

To help with cleaning, antibacterial solutions can be tailored to specific areas of a facility, such as the production, storage and packaging areas where food is most likely to be handled and transported.

Polyurethane systems that incorporate antibacterial additives are available in the market, such as the Flowfresh range from Flowcrete. This range incorporates Polygiene®, made up of silver ions that can help to eliminate 99.9% bacteria from the floor’s surface.

The Flowfresh range incorporates antibacterial additives to reduce bacteria on the surface

Increasing the sanitation of a facility can dramatically reduce the likelihood of contamination, meaning that the tailored dietary requirements of the consumers remain pure and staff remain safe when working.

Slip Resistance

To further increase the safety of a food and beverage site, in areas where it is needed the most slip resistance can be specified. In resin flooring, aggregates are used to form a coarser surface, increasing traction.

Textured surface improve slip resistance

Whilst this is very beneficial in wet processing areas of the site, utilising more aggregates in the production areas can be problematic, as the coarser the floor, the harder it becomes to clean, meaning that dirt and bacteria can get caught in the floor’s bumpy texture.

The ability to tailor this type of flooring means that you can maintain a good balance between ease of cleanability and slip resistance.

Thickness

In a similar vein, the thickness of the flooring can be tailored to different areas of a facility. Thicker flooring can naturally handle more wear and tear, and so is well suited to areas where heavy machinery is situated, as well as areas of high footfall.

Thicker flooring can be specified for areas of heavy machinery

Often, the thicker the flooring the more costly it becomes and so only using it in areas where it is needed makes sense both logically and financially. Thinner flooring options could be used in on-site offices for example, where footfall would be much lower.

We don’t see tailored dietary requirements going anywhere any time soon, so make sure your facility is tailored to your every need. For more information, please feel free to leave a comment below, and our flooring experts will be in touch.