The remarkable Hong-Kong-Zhuhai-Macau Bridge, also known as HZMB, is the $20 billion development built to link the three cities of Hong Kong, Zhuhai and Macau for the first time.

Construction Challenges

The scale and ambition of the project was truly unique, as the 55-kilometre (35 mile) bridge-tunnel system includes a series of three cable-stayed bridges, an undersea tunnel and four artificial islands!

Building a 55-kilometre bridge tunnel was a unique feat

This unique feat of civil engineering certainly faced some unique challenges, thanks in large part to the vast distances that it covers and the fact that it would be supporting tens of thousands of passengers each day.

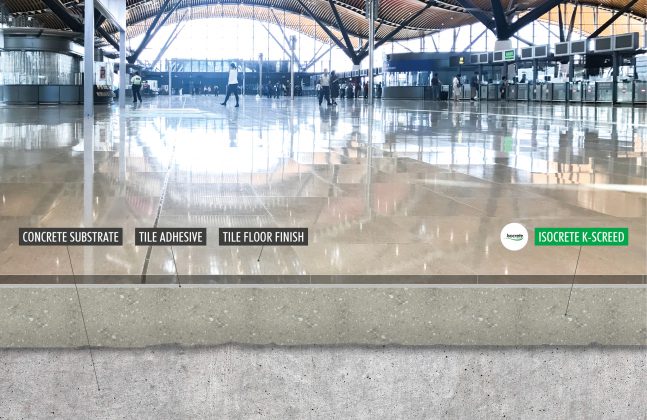

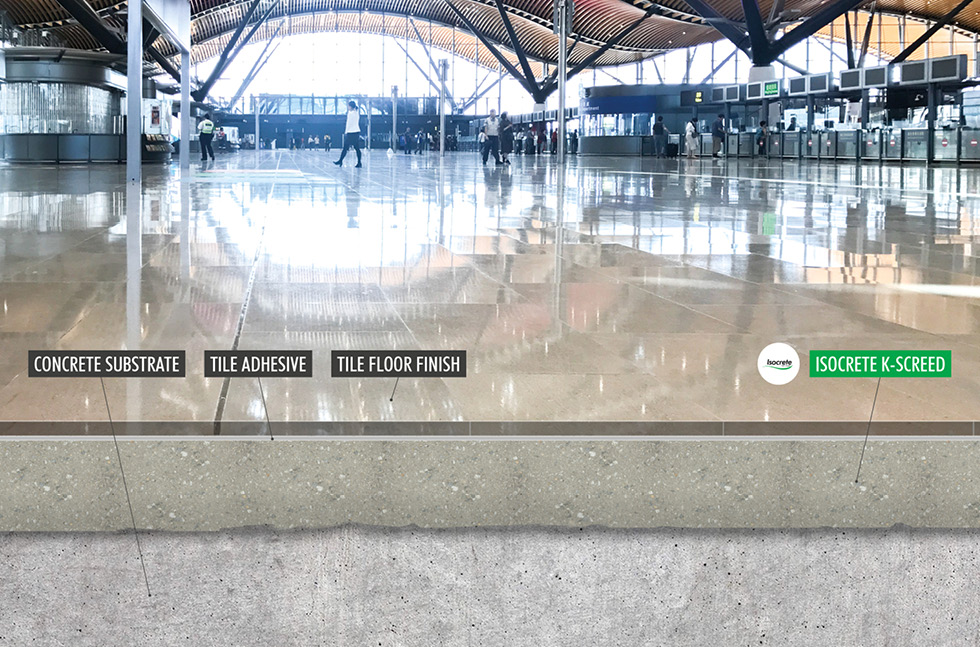

Screed Support

Situated on a 130-hectare reclaimed island, the innovatively designed Hong Kong Boundary Crossing Facility (HKBCF) provides a strategic multi-modal transportation hub for the western Hong Kong side of the bridge. If the floor failed here then it could lead to a long list of safety and operational concerns!

The HKBCF needed to cope with the pressure of thousands of passengers each day

To make sure that HKBCF would be able to cope with these pressures, 43,000 m2 of cementitious subfloor screed solution was applied. With strength being a key factor here, the tried and tested subfloor screed Isocrete K-Screed from Flowcrete Hong Kong was chosen.

From the Experts

Speaking to All Things Flooring, Francis Tang, General Manager of Flowcrete Hong Kong, said: “The Hong Kong–Zhuhai–Macau Bridge is central to the Hong Kong government’s plan to improve connectivity in the region and we’re proud to have been involved in the construction of an important section of the bridge’s infrastructure.

The flooring needed to be as robust and reliable as possible

“The vast numbers of people that the crossing facility would have to accommodate on a daily basis meant that the floor in the HKBCF had to be as robust and reliable as possible. Isocrete K-Screed was ideal for this, as it has been specifically designed to rapidly provide a high-performance, long lasting screed layer for large and demanding construction projects.”

Isocrete K-Screed is a robust semi-dry cementitious screed system that incorporates a proprietary additive to produce an early drying, high-strength screed. These properties mean that large-scale developments can speed up the process of applying the screed without sacrificing on critical structural and functional properties.

High strength screed was applied on top of the concrete substrate

The specialist screed system was applied in thicknesses ranging from 75-150mm across the site, including in the customs, clearance and departure halls as well as in the baggage handling area, back-of-house maintenance facilities and the overhead rooftop garden. Inside the HKBCF, Isocrete K-Screed proved to be the ideal platform on which to install the tile finish, creating an attractive and impressive floor area!

If you would like any more information on subfloor screeds for your project, please contact us – we’d be happy to help!