At some point in our lives we’ve probably all shuffled across a carpet in our socks in the hopes of building up enough static charge to give our pal a little shock when poking them. This is actually often the first thing that comes to mind when we think of static charge.

Whilst these little shocks may be harmless to humans, they can be detrimental to state-of-the-art technology that involves delicate components.

Although most of us may think of computer viruses when it comes to threats to technology, sensitive circuitry can just as easily be ruined by a single touch from a statically charged finger.

Sensitive circuitry can be ruined by a single statically charged finger

In fact many components can be destroyed by a charge of just 300 volts, however one person walking across the floor can quickly generate up to 3,000 volts!

How does charge build up?

This voltage builds up through a process called triboelectric charging, which basically means that when someone moves on a floor, they build up a negative charge and if the person is not insulated then this charge increases the more they move around – shocking isn’t it?

If the charge is large enough, then when an earthed object nears the charged object the charge will jump through the air to go to earth. This results in a spark, which, if a person is the earthing object, will be experienced as a mild shock.

Charge can damage sensitive equipment beyond repair

However if it is a piece of equipment that the charge has gone through then it could just have been damaged beyond repair.

Which industries are in danger?

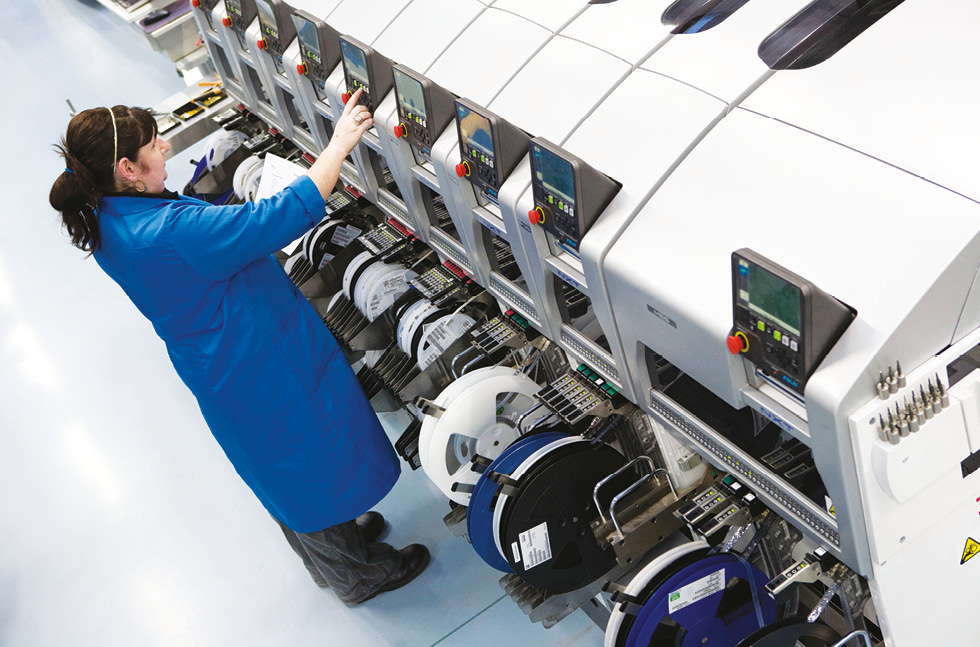

This obviously has significant implications for anywhere that relies on delicate computer equipment, such as data warehouses, R&D sites, clean rooms and laboratories. It’s a particular problem for the electronics manufacturing industry, which loses significant sums of money every year in damaged goods and broken equipment.

For some sectors, static electricity poses an even more dangerous risk – as if there are any explosive substances, gases, vapours, fogs or dust present then a small electro-static discharge can be an ignition source. This is often the case with environments such as munitions manufacturing, hyperbaric chambers, oil and gas facilities and military installations.

To avoid this problem, anti-static floor finishes can be installed that actively remove any charge being built up in a person and safely take it away to an appropriate earthing point.

How does anti-static flooring work?

Anti-static floors are ordered into categories depending on how quickly electricity can move through them, a property which is measured in ohms. Surfaces with the least resistance are defined as conductive, dissipative floors allow electricity to flow through at a controlled speed and the most resistant floors are called insulative.

Flooring can be defined as conductive, dissipative and insulative

Anti-static floors work by incorporating specialist conductive materials that take away any charge a person has built up as soon as their foot comes into contact with the coating. This contact kicks off a chain reaction that results in the charge being safely removed down through the floor and away from the sensitive working environment.

Next, the charge hits a conductive primer that has been filled with carbon to ensure a very low level of resistance. Finally, the charge goes into a copper tape buried under the floor coating which is connected to a safe earthing point.

Bear in mind that this is an ideal scenario and in practise there may be more or less steps.

Some Points About Earthing Points

One thing that the floor definitely needs is the earthing point, without this the floor cannot be considered anti-static, as charges that go into it will simply build up. In practise an earthing point is usually a highly conductive metal rod driven deep into the building’s slab, however other options could include using the building’s steel beams or using a plug socket.

Typically, one earthing point per 200 square meters should be sufficient, but the exact requirements need to be specified by an electrical engineer to ensure that the resistance measurements are appropriate.

Earthing points are needed to consider flooring as anti-static

To determine if the floor is up to the task at hand, its electrical resistance should be tested at each stage of the application. The BS EN 61340-5-1 standard includes a method for determining the resistance of a floor through point to point conductivity testing. The result of this will determine whether the floor can be categorised as conductive, dissipative or insulative.

When testing the floor, it is best to move the contact points around to ensure that a footprint sized space has been checked, as this is the practical contact area through which any charge held by a person will be transferred.

Making sure that a floor finish meets a site’s anti-static needs requires an understanding of the location’s operational activity, how the floor build up works to remove this threat as well as the role that other factors such as testing and personnel clothing play.

To get a full picture of all of these factors and how they interact, it is important to talk through the flooring specification and materials with the manufacturer and contractor to ensure that the final coating will provide the required standard of conductivity.

If you would like any further information on anti-static flooring, please leave a comment below or give us a call, we’d be happy to help.