When you sit back after a long week at work with your well earned beer, the last thing you want to think about is the bacteria that may be lurking within your lager.

As consumers, we take it as a given that the produce we buy is free from contamination and germs that could cause us harm. Just last year we heard of several serious contamination cases that were traced back to the production and packaging sites, so going the extra mile to improve sanitation in such facilities is paramount.

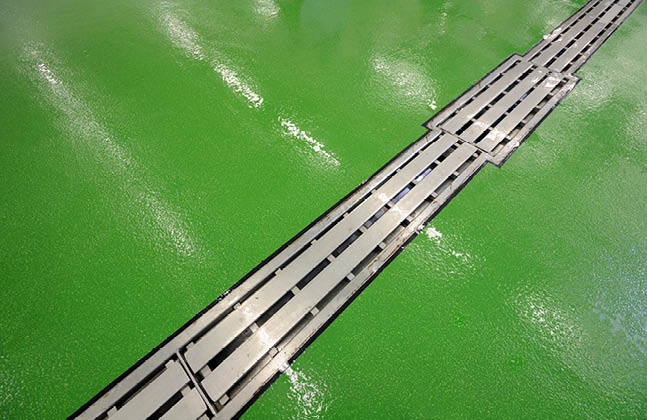

One very effective way of reducing the likelihood of harmful contaminants building up within your brewery is to install flooring with bacteria inhibiting properties, that works alongside a regular cleaning regime to eliminate unwanted germs, pathogens and bacteria.

A regular cleaning regime can help to eliminate unwanted germs and bacteria

According to the FSANZ standards and codes, flooring in food and beverage facilities at the base level should be seamless, impervious and hard wearing. Thermoplastic coverings such as terrazzo, epoxy resins and cementitious polyurethane screeds all meet these regulations, thanks to the non-porous, easy-to-clean surface.

However, even with the correct flooring at this basic level, if yeast, hops or barley fall to the floor, unwanted bacteria can still grow between clean downs – putting the sanitation of your brew house in jeopardy. Bacteria could be carried to different areas of the brewery on the shoes of staff, or on the wheels of apparatus. If this bacterium reaches areas of production or packaging, you could be looking at polluted pints.

Luckily, there are systems on the market that feature bacteria inhibiting properties. One such system is the cementitious polyurethane Flowfresh range from Flowcrete.

The Flowfresh system contains an antibacterial additive

The Flowfresh range incorporates Polygiene®, an antibacterial additive that kills up to 99.9% of bacteria on the floor’s surface when teamed with a thorough cleaning regime. Unlike synthetic additives or surface treatments, the homogenous distribution of the additive means that it remains active for the lifetime of the floor, even if worn of damaged.

Therefore, should the flooring become damaged over time, with the weight of brew kettles or dropped tools, kegs or tasting glasses, any germs within cracks or gaps in the floor will still be exposed to the active antibacterial agent!

But how does this work?

Polygiene® is an all-natural solution that uses the power of silver ions. No other flooring solution utilises the natural germ killing properties of natural silver in this way.

The Polygiene® additive consists of a thermosetting amino compound. Locked into the main resin matrix of the flooring material, it continuously emits powerful silver ions over an extended period of time. These ions target germs on the surface of the floor, penetrating the cell membrane of the bacteria and causing irreparable damage to the pathogen.

The effectiveness of the system meets both the ISO 22196 and JIS 222801 standards for measuring a surface’s antibacterial efficiency. What’s more, this polyurethane system is HACCP Internationally certified.

Flowfresh is HACCP Internationally certified.

The Hazard Analysis and Critical Control Point (HACCP) food safety management system is a preventive risk assessment tool utilised by the food industry to ensure that all food safety hazards are assessed and appropriate controls are put into place to eliminate or reduce contamination of food from those hazards.

With such a flooring system in place, brewers can focus on honing their craft whilst the floor takes care of uninvited guests.

Is it time to upgrade the flooring in your brewing facility? Take a look at our other brewery blog posts here.