When Hong Kong built a new velodrome, its designers knew that it was essential that it would be up to the task of delivering elite sporting events when the eyes of the world are focused upon it!

This meant that each aspect of the venue would have to be of an exceptionally high quality to ensure that the demands of the site wouldn’t cause any part of the building to deteriorate or fail.

When it came to the floor, the Hong Kong Velodrome knew that it needed to provide a safe, easy to clean surface in the face of heavy pedestrian traffic from the 3,000 spectators, frequent cleaning, scuffs, scrapes, scratches, impacts and abrasions.

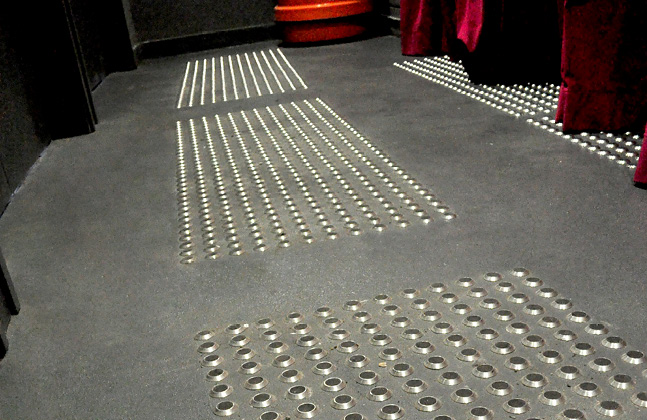

To create a surface that could meet this challenge, 15,000m2 of Heavy Duty Isocrete K-Screed and 10,000m2 of the high-build epoxy resin coating Flowcoat SF41 were applied across the spectator stand, the central basketball pitch and in the back of house areas.

The flooring project took 15 months to complete – and it was critical that it was finished on time, as the velodrome had a packed schedule of sporting events, including the UCI Track Cycling World Cup.

Thanks to the expertise of Flowcrete Hong Kong’s approved applicator, the floor was finished in time for the competition, which saw Team Great Britain win the final round of the UCI Track Cycling World Cup on the 250-metre cycling track (the team also came away with the 2015-2016 overall title in the process, succeeding previous champions Germany).

A History of the Hong Kong Velodrome

The Hong Kong government agreed to build the Velodrome following Wong Kam-po’s gold medal victory in the men’s road race during the 2006 Asian Games in Doha, amid concerns that athletes who represent Hong Kong had to rely on training facilities in China.

Construction of the HK$1.1 billion venue got the legislative go-ahead in January 2010 and work began two months later. The Velodrome occupies a total landmass of 6.6 hectares and cycling helmets inspired the structure’s signature wavy rooftop design.