This week’s installment of the Flooring Clinic: Flooring Advice to Live By covers the correct specification framework that should be followed when choosing a floor finish for both commercial and industrial sectors.

Handy hint number three…

Follow a Specification Framework

While it’s easy to choose a floor based on the recommendation of a facilities manager from another firm, a quick discussion with a sales person at a trade show or previous experience with the manufacturer, it’s important to thoroughly work through the functional requirements as well as site and substrate conditions prior to making a decision.

Let’s take a look at some of the questions that should be asked as part of the specification framework…

Firstly, the functional requirements…

- What is the application type?

Commercial, industrial, food & beverage, pharmaceutical etc.? Different application types will require different flooring features. - What category does the anticipated level of traffic fall under?

Light, medium, heavy or very heavy duty areas differ greatly in their impact and abrasion resistance requirements. - What type and size of loading is anticipated?

Will heavy plant machinery be installed or will heavy goods be transported throughout the facility? - What chemicals will be used in the facility?

Ensuring that the floor finish is resistant to the chemicals present on site will reduce the risk of corroded flooring. - Will the area be subject to extreme temperatures?

Will daily hot wash-downs be carried out? Are you specifying for a cold store or freezer? - Are there any aesthetic requirements to consider?

Is a gloss finish preferable over matt? Will the floor need to be UV stable or create a visual impact?

Secondly, the site conditions…

- What is the substrate?

Are you looking to cover an existing floor? Is the concrete new? Or are you working with old, damaged concrete that will require preparatory work? Failing to prepare is preparing to fail – read part 1 of the Flooring Clinic for more on substrate preparation! - Are there any joints in the existing substrate?

- Are there any site conditions that will need to be considered during installation?

Extreme weather, rain and traffic are just some of the external factors that can lead to floor failure.

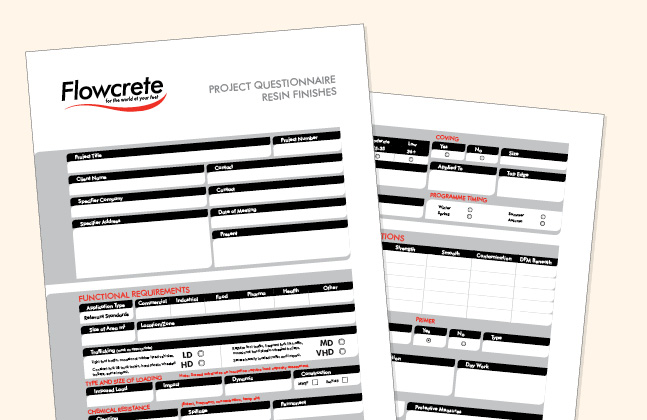

In Flowcrete UK’s online Specification Zone, you’ll find a copy of their Resin Flooring Project Questionnaire, which can help to guide users through the correct Specification Framework.

Looking for more handy hints? Check out more from the Flooring Clinic…